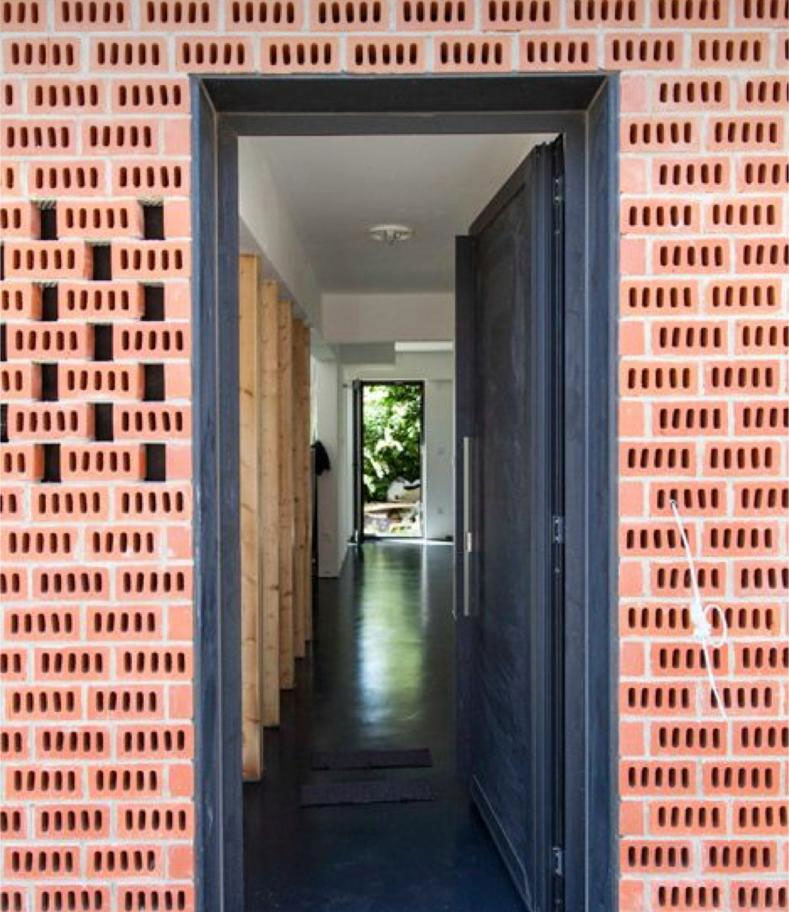

These are bricks that contain holes or perforations. These openings are intentionally incorporated into the brick design to serve various purposes.

Strength and Durability:

Perforated bricks have a compressive strength of around 3.5 N/mm2 and are suitable for reinforced masonry construction. They are lighter in weight than solid bricks (60% lighter than a solid concrete block) and are easier to pass electrical wires and plumbing fixtures through them.

Thermal Insulation:

Perforated bricks offer good thermal insulation properties due to the air gaps present in their design. The thermal insulation properties can be further enhanced by filling the empty air partitions with insulation materials, making them an energy-efficient solution for wall construction.

Fire Resistance:

Perforated bricks can provide fire resistance due to their non-combustible nature and are commonly used in fire walls and fire barriers. The fire resistance ratings of perforated brick walls depend on the thickness of the walls and the materials used in their construction.

Low Maintenance:

Perforated bricks are known for their low maintenance requirements. They are made of impact-modified polypropylene, which is a durable and long-lasting material that can withstand various environmental conditions. The material is also chemical-resistant, making it suitable for use in different applications.

Eco-Friendliness:

Perforated bricks are an environmentally friendly alternative to traditional bricks. Since they use less raw material due to their hollow design, they reduce the overall environmental footprint of a project. Moreover, their lightweight structure reduces transportation costs and emissions, aligning with the goals of green construction.

Versatility in Design:

Finally, perforated bricks offer unparalleled versatility in design. Their unique patterns and perforations allow architects to create visually appealing facades, walls, and partitions that combine functionality with aesthetics. These bricks are increasingly popular in modern architecture for their ability to balance practicality with artistic expression.

Contact us any time.